Die Simultion Technologies

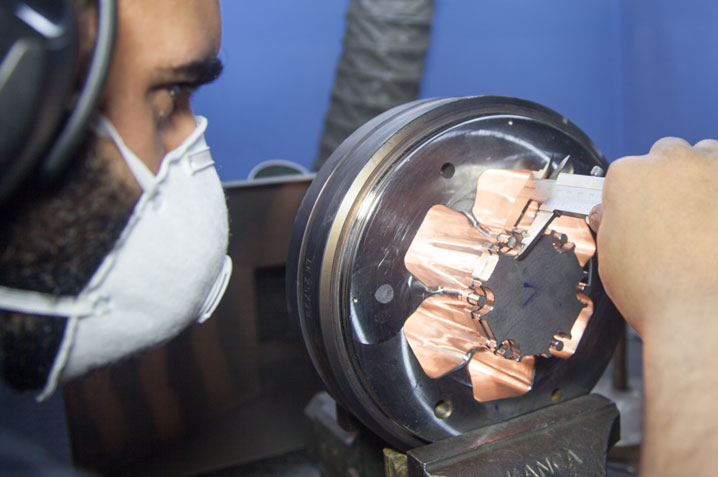

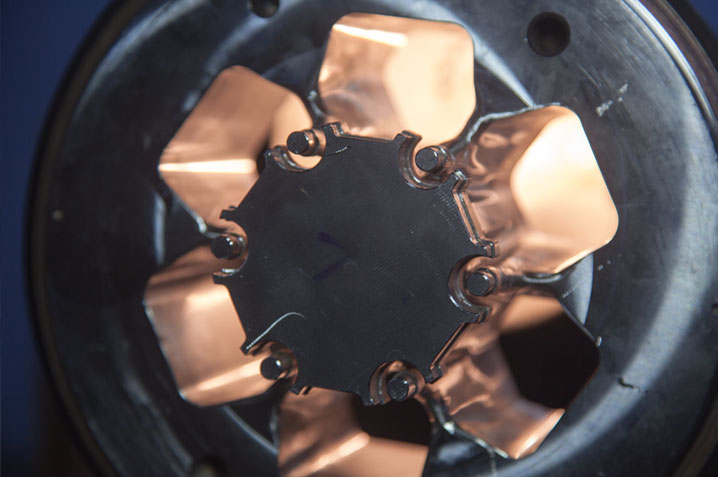

Proactive approaches in the production of aluminum extrusion profile dier

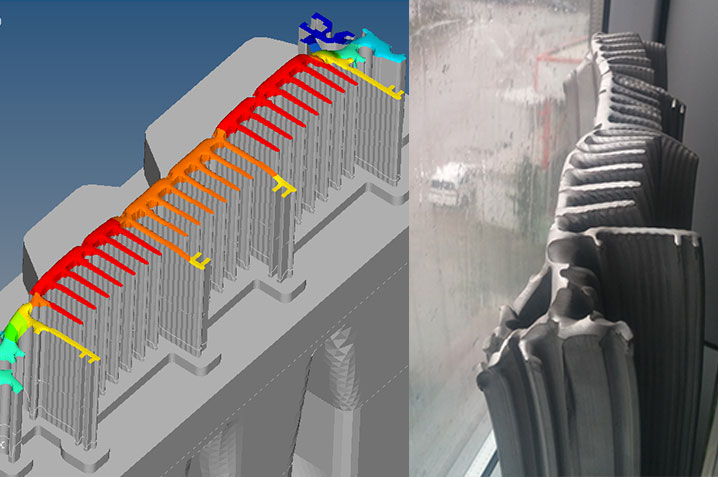

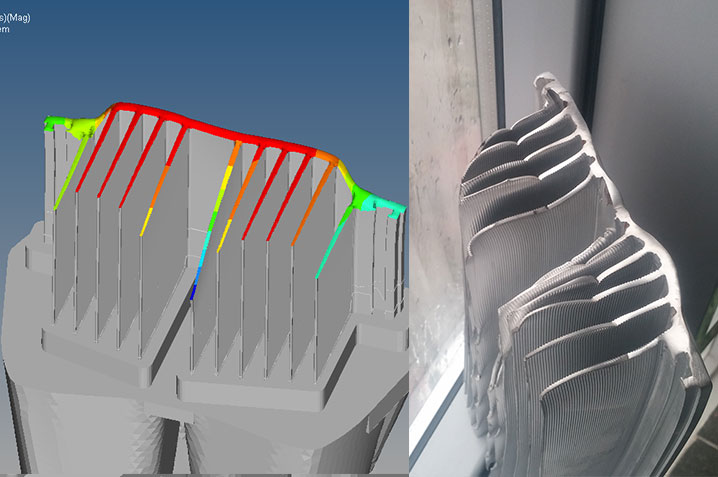

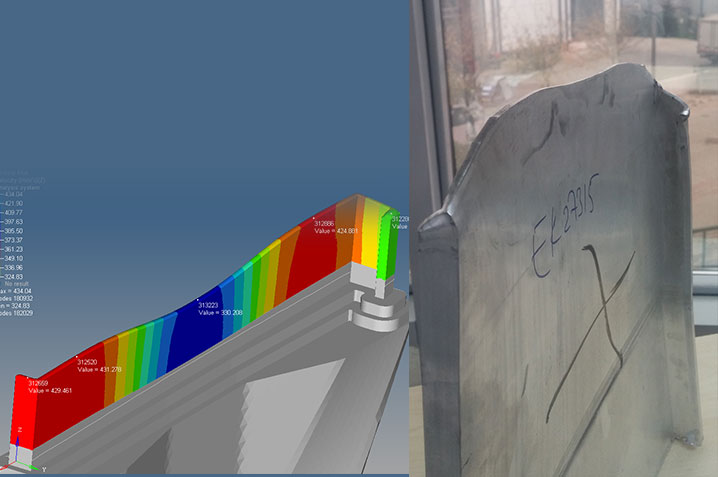

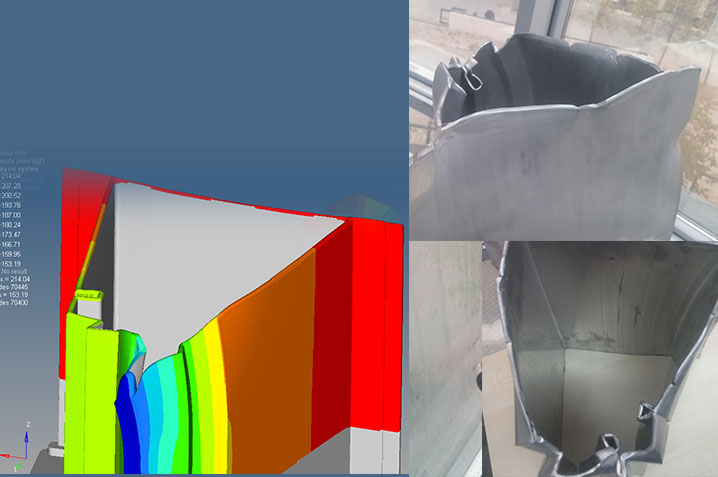

The simulation technology, which is a product of innovative approaches in the sector of aluminum extrusion profile die design and production, standardizes the quantity and quality in the production with appropriate modeling possibilities and minimum error rate.

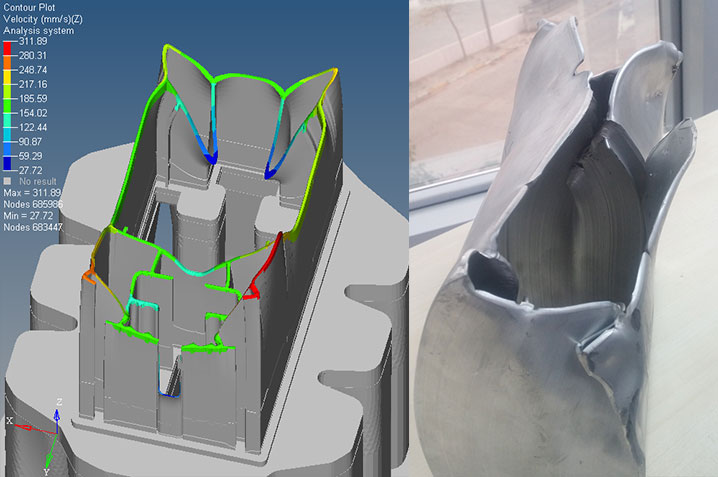

The material-labor-time loss, arising from traditional modeling and production methods in the sector of aluminum extrusion profile die design and production, depending on high margin of error will be prevented with simulation technologies.

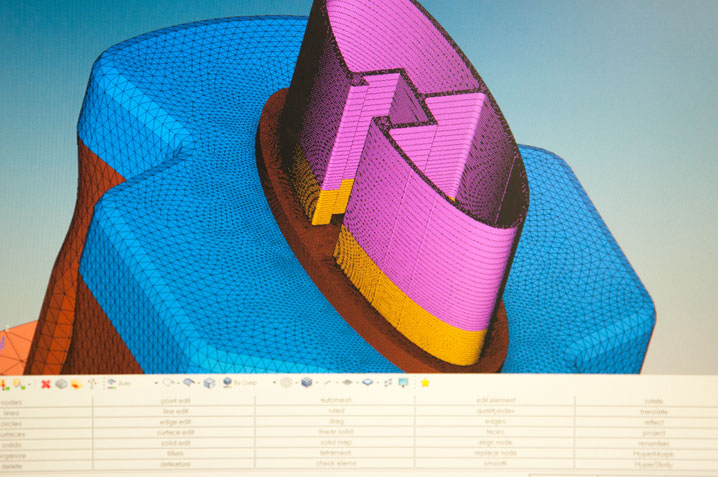

The measurement accuracies, practical modeling, die transitions and geometries, which are difficult for modeling, which cannot be obtained using conventional methods in the flow of aluminum extrusion profile die design and production, are possible through simulation technologies.

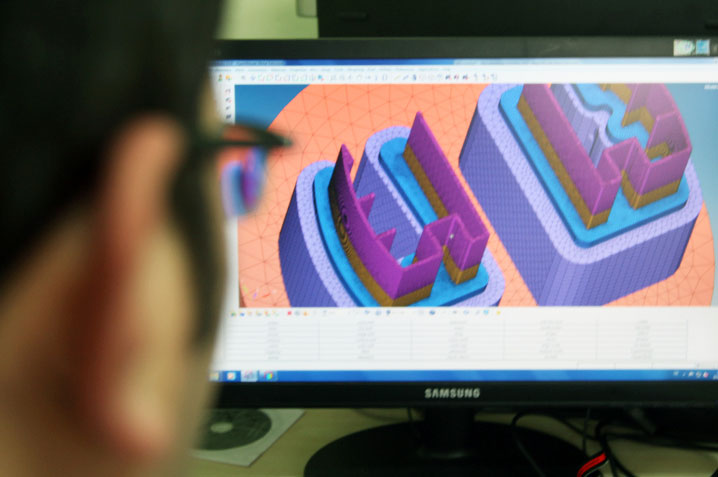

Before conveying the drawings of aluminum extrusion profile die, modeled by the eksenAl design office to the production course, the simulation software of the model in the digital environment and analyzing process through eksenal experience, serves to determine and to remove the errors if exist.

Together with analyzing of the data, obtained through die simulation, beside making needed alterations, also necessary information of revision, to extend the die productivity and life will be reached.

By analyzing these simulation outputs through eksenAl experience, troubled situations on the die will be established before starting

technology with eksenAL

eksenAl follows up the actual technology by force of proactive understanding.

In profile die designs, simulation software is dealt within this frame. The simulation software provides to establish probably troubles of the die in computer environment before the production by using the data from experience.

eksenAL

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

KOBİ OSB 29.Sk NO:25 Köseler Mahallesi DİLOVASI / KOCAELİ

eksenAL -Alüminyum Ekstrüzyon Kalıp Teknolojileri' nin üretim sürecini ve firma profilini anlatan video