Standardized QUALITY with eksenAL

Responsibility being eksenAL

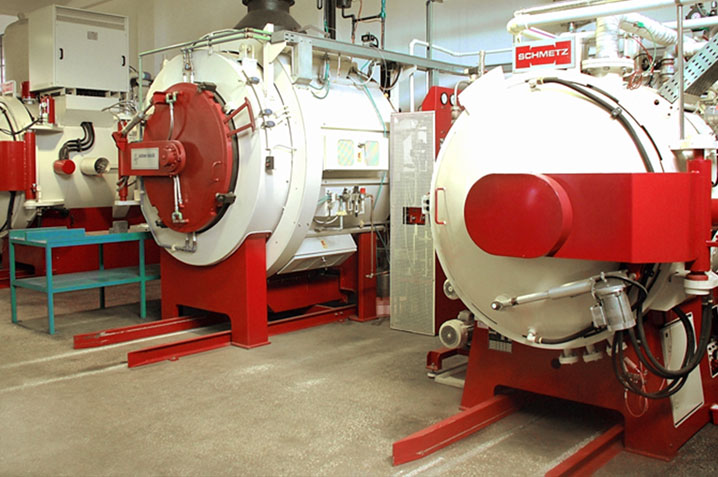

eksenAL, combining the experienced human resourcess and advanced technology with innovative understanding...

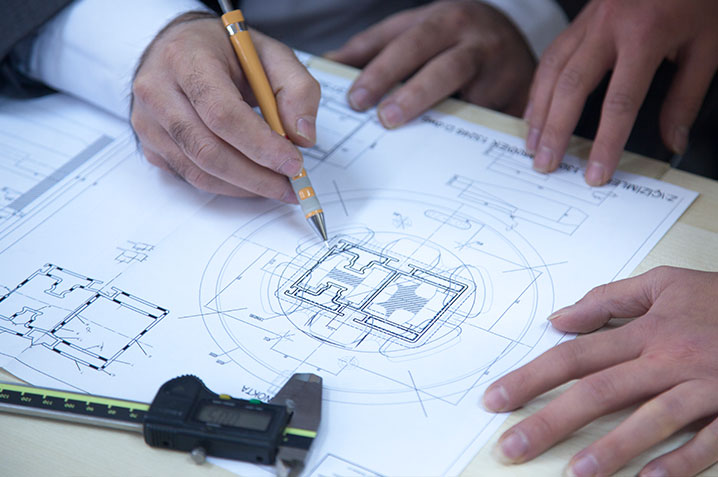

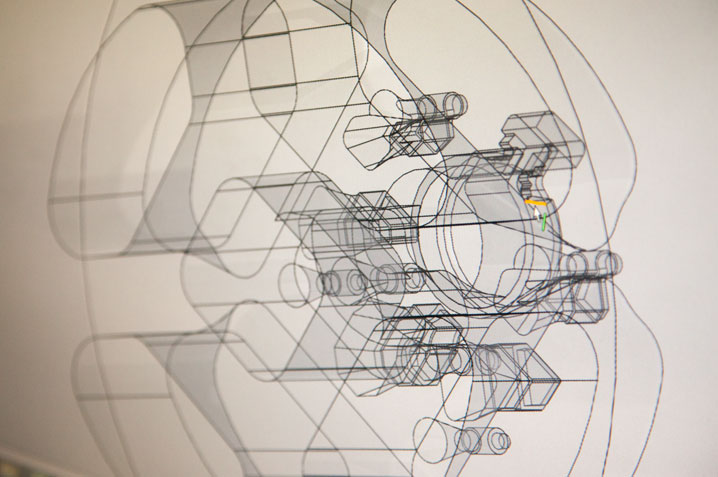

R&D Works

As eksenAL, it is our principle to follow up the actual technology and make use of new possibilities given by the technology. further

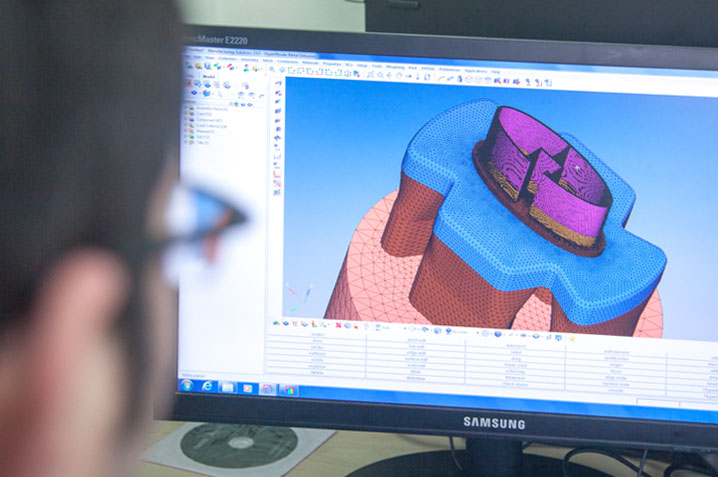

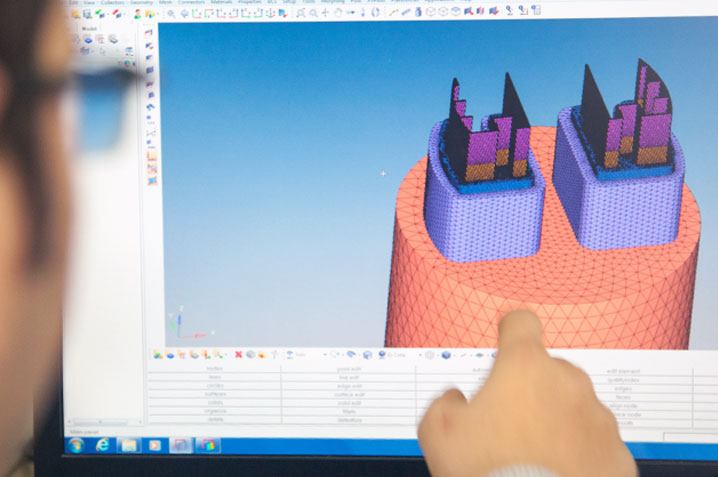

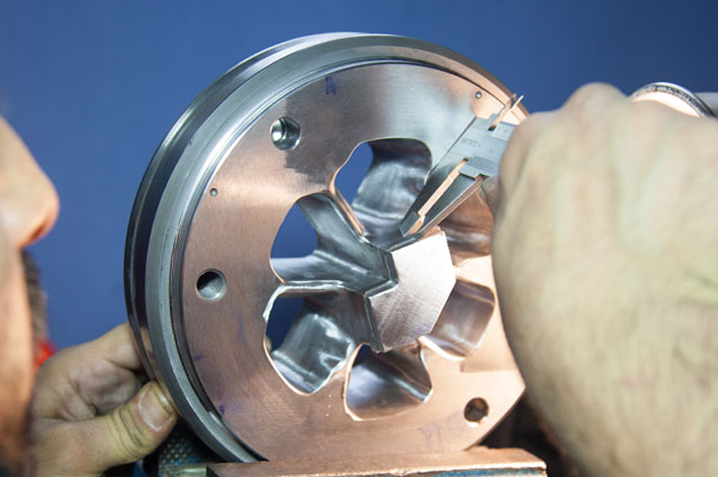

Simulation applications

Doing analyses before production on aluminum extrusion profile die modeling...

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

KOBİ OSB 29.Sk NO:25 Köseler Mahallesi DİLOVASI / KOCAELİ

eksenAL-Aluminum Extrusion Profile Die Technologies' nin üretim sürecini ve firma profilini anlatan video